Context

Tecnoalcalá is a scientific and technological park established in 2003, located in the city of Alcalá de Henares, northeast of Madrid.

Tecnoalcalá encompasses companies from different sectors, the most representative of which is IT, healthcare and industry.

One of the demosites of WEDISTRICT project is located in this area: A big solar laboratory supported by biomass will be deployed in order to evaluate various WEDISTRICT technologies for heat and cold generation. This demosite will supply heating and cooling needs to a building through a new heat and cold network, which will operate following the advanced digitalisation system developed in the frame of the project.

Tecnoalcalá demo-follower will explore the possibility of having a whole Technology Park covered by District Heating and Cooling network.

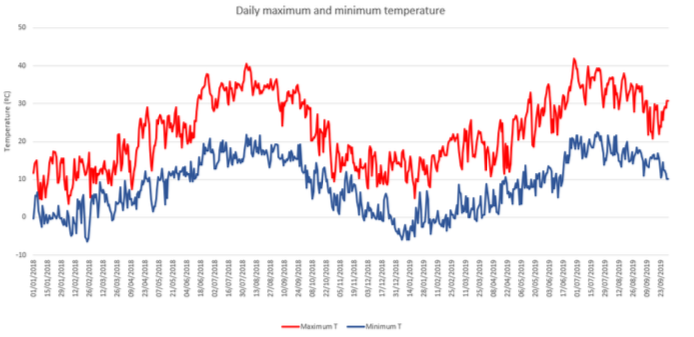

The data observed in 2018-2019 shows temperatures over 40C in summer and below 0C in winter, meaning that this site requires both heating and cooling supply for keeping good indoor comfort temperatures.

The sustainability is at the heart of this study, so the “localness” of the resources is a key parameter.

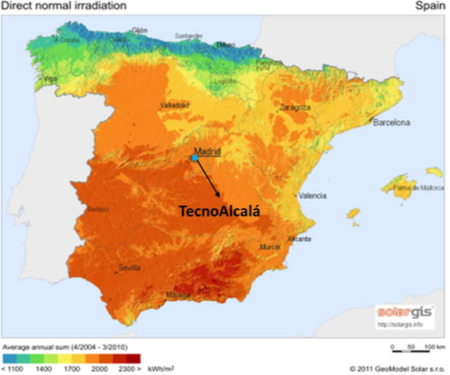

Spain is one of the most attractive countries for the development of solar energy, as it has the greatest amount of available sunshine than any country in Europe. In particular, the Direct Normal Irradiation in Alcalá de Henares is 1,980 kWh/m2 year, which makes the solar resource a promising solution to be used.

Another good option for renewable assessment in Tecnoalcalá could be the implementation of geothermal system, considering the good resource potential for medium-low temperature.

Area

The Park is developed on a 370,705m2 plot, located on the campus of the University of Alcalá.

More than 40 companies are located in the technological park, mainly offices and laboratories.

There is one building installed in Tecnoalcalá, which is of special interest: a big Data Center located in the corner of the area. The Tecnoalcalá Data Center is one of the largest data processing centers in the world. The transformation of Nabiax’s systems in Europe is carried out in this facility, together with the hosting and housing services for their clients.

Developed in five phases, it consists of a total of 23 IT rooms of 681 m2 each, 50 MW installed and developed through the basic concepts of modularity, flexibility, redundancy, and efficiency. Its design, construction and operation obey the strictest levels of sustainability with significant reductions in water consumption, energy and CO2 emissions compared to traditional Data Centers.

In the frame of this activity, the option of utilisation of waste heat generated by the building for the District Heating will be assessed (through the fuel cell technology for boosting the temperature to suitable levels).

Energy demand

In order to perform a very first preliminary assessment and propose different DHC RES-based solutions, data from a building reference has been used. This building consists of different administrative and laboratories areas, with a current installation of gas boiler for heating needs and chiller for cooling needs.

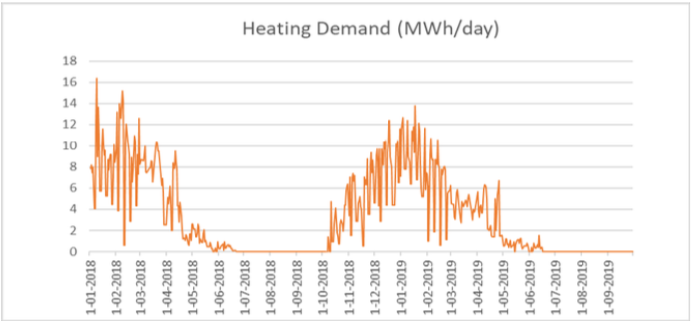

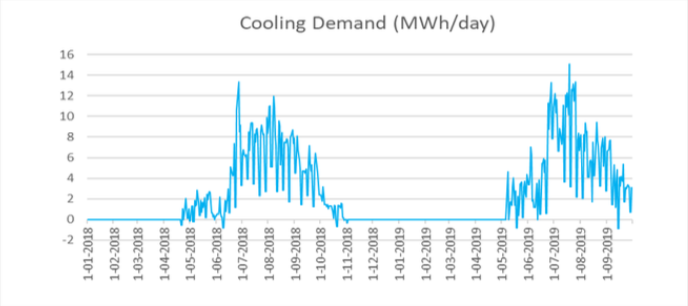

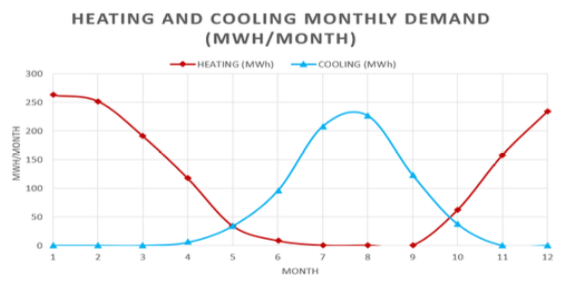

The heating and cooling demands are shown in the next figures:

The global consumption with monthly data in a full year could be summarised in the next image:

We can see the need for both heating and cooling with similar maximum loads (2018 data). There are three clearly defined seasons:

– Heating Season: From November until April with higher values in December, January, and February.

– Cooling Season: From June until September with higher values in July and August.

– Intermediate Season: In May and October, where heating and cooling have to function in parallel.

This data supports the idea of studying a complete district heating and cooling option. For such heat and cold generation, and taking into account the RES potential presented in the previous description, both solar and geothermal resources should be analysed. Both technologies require a big amount of available space, in the case of the solar option also shadows have to be taken into consideration. Tecnoalcalá has enough available space where both systems could be installed.

Proposed technologies

Solar technologies

Integration of solar collectors for making useof the solar resource in Tecnoalcalá.

Biomass boiler

Biomass boilers installation for covering peak loads or energy not covered by solar collectors.

Molten Salts

Thermal storage integrated with concentration solar panels (PTC and Fresnel).

Hybrid PV-Geothermal

Hybrid PV-Geothermal Installation of PV panels and Geothermal system (boreholes and heat pump) in order to cover heating and cooling demand, considering the good potential in the site and the needs of heating and cooling needs along the year.

Advanced Absorption chiller

Integration of advanced absorption chiller for covering cooling loads and fed by renewable sources (solar power).

Renewable air-cooling unit (RACU)

System integrated in the buildings and fed by the district heating system.

Waste heat recovery with fuel cells

Heat recovery fuel-cell based from the Tecnoalcalá Data Center.

Waste heat recovery and heat pump

Heat recovery from the Tecnoalcalá Data Center with heap pump (instead of fuel cell).

PV panels

PV panels integrated for covering electricity consumption from the thermal station (and equipment installed).

Hot water storage

Optimised water storage sized for acting as solar buffer.

Proposed solutions

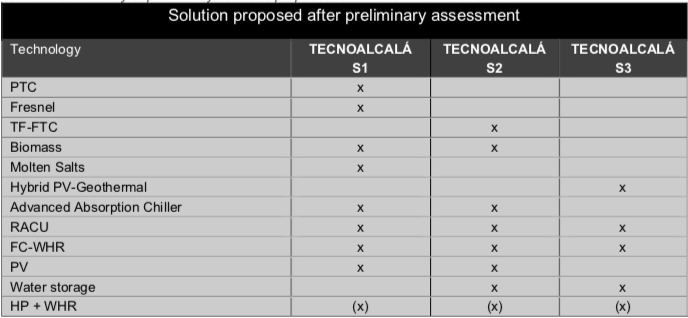

The combination of the different technologies generates three main solutions which will be studied in the next step (other solutions might arise during the activity):

Solution 1

This combination integrates concentration solar panels (Fresnel/PTC) with molten salts storage for thermal buffer and biomass boiler for peak loads or energy not covered by the solar collectors. It will include cooling generation with the advanced absorption chiller technology, being an overall DHC system.

Furthermore, waste heat from the existing data center will be considered (by means 2 subscenarios, using the FC or a HP) and RACU system integrated in particular buildings for air conditioning.

The possibility of installed PV panels will be studied in order to cover the electricity consumption of the own thermal station, taking into account the solar potential in the site.

Expected Impact

Maximised solar resource

Waste heat recovery to be injected in the DH

Improvement of absorption chiller performance

Evaluate availability of biomass and cover extra heating load

Avoidance of the CO2 emissions

associated with the current heating and cooling systems

Plan new development of tertiary buildings as equipped with RACU

CAPEX and OPEX comparison with the current status

based on individual heating/cooling equipment.

Solution 2

This solution has a similar concept like Solution 1 with the difference of using the TC- FTC system as solar collector. This technology operates at lower temperatures than PTC or Fresnel and, for this reason, it will integrate water storage as thermal buffer instead of the molten salts option.

FC-WHR will use the extra heat generated by the Tecnoalcalá Data Center (extending the WHR study thanks to a subscenario with HP instead of FC) and RACU system will be studied at building level.

PV panels could be also installed for covering the electricity consumption of pumping and equipment within the installation.

Expected Impact

Maximised solar resource

Waste heat recovery to be injected in the DH

Improvement of absorption chiller performance

Evaluate availability of biomass and cover extra heating load

Avoidance of the CO2 emissions

associated with the current heating and cooling systems

Plan new development of tertiary buildings as equipped with RACU

CAPEX and OPEX comparison with the current status

based on individual heating/cooling equipment.

Solution 3

This combination integrates the hybridation concept with PV panels and geothermal system, considering the geothermal potential of the site, as shown previously.

The heating and cooling loads are quite compensated along the year what makes geothermal energy a good solution considering environmental aspects as well, for a new DHC.

FC-WH, HP + WHR and RACU systems will be integrated as part of the solution, as in the previous solutions proposed.

Expected Impact

Maximised geothermal and solar resources

Waste heat recovery to be injected in the DH

Avoidance of the CO2 emissions

associated with the current heating and cooling systems

Plan new development of tertiary buildings as equipped with RACU

CAPEX and OPEX comparison with the current status

based on individual heating/cooling equipment.